It's Friday April 26, 2024

News From The Village Updated Almost Daily

Lots of boats come to Oriental, some tie up at the Town Dock for a night or two, others drop anchor in the harbor for a while. If you've spent any time on the water you know that every boat has a story. The Shipping News on TownDock.net brings you the stories of the boats that have visited recently.

October 25, 2017

At the back of Triton Yacht Sales, under cover of a temporary white structure, a wooden boat had been sheltering on the hard, undergoing extensive cleaning and restoration. The end of September saw the shelter removed and Spark, a 36’ Presto-Type Sharpy (yes, you read that correctly), made ready to return to the water after four long years.Spark, as a seaworthy visiting vessel in Green’s Creek, a few years ago, before Joel found her.Spark, after restoration, waits for the water.Joel Kellogg, the current owner of Spark, developed a love for gaff rigged ships while sailing aboard the Lady Washington. “Every time we were sailing, like in the San Francisco Bay, on our big, square-rigged ships, there’d be old gaffers sailing up, wanting to get close and sail with us. I always loved watching them sail… sail all around us. I always thought to myself, that’s what I’m going to have one day.”

At Triton Yachts, Joel talks about the work he’s done and the work to come.Years later, in 2013, he saw pictures of Spark and was able to look beyond what she had become to what she could be. He loved her lines, her rig, and the cedar-plank-on-oak frame construction. “It was advertised for like, $1,000 or something. And it was basically, ‘come and get it.’ And then, when I agreed to come take care of it, it sank at the dock.”

Despite the additional hassle of cleaning Neuse muck out of her hull, Joel paid for Spark as agreed and had her towed to Sailcraft to assess the damages. Deciding it was going to be an extensive repair and cleaning, he settled Spark in on the hard at Triton Yachts.The first meeting was more water-logged than expected. (Photo provided by Joel Kellogg)Out of the water and under cover at Triton Yachts. (Photo provided by Joel Kellogg)Joel, who lives in Asheville, spent the next few years crossing NC to and from Oriental. Around the same time he acquired Spark, he also began work as a trim carpenter. The skills transferred well.

Working on Spark has taught him a lot. “I spent weekends, a lot of weekends [in Oriental]. We don’t work Fridays, so I’d leave Thursday night after work. Drive down six hours, and work Friday, Saturday, and half a day Sunday on the boat. Then drive back and do it again.”

Found in the bottom of the Spark: a Jotul cast-iron wood stove.Joel says he removed 800 pounds of muck and trash, including a large steel drum, a cast-iron wood-burning stove, and lead window sash weights used as ballast in the bilge. He kept the stove and two rubber ducks he found floating inside. The rest was hauled to the dump.

Salvaged stowaways found floating in the bilge.Spark’s original design had a centerboard. The previous owners got rid of it and bolted a large block of lead underneath. “It was just a big block of lead that they bolted, like a square. Square in front, square in the back. So I brought down a big oak tree and I milled it. I made the nose taper up like that, properly.”

Joel at work topside, making ready to move Spark to the water.His estimates put the added ballast at 1,100 pounds. The lead will stay for now. He wants to see how she will sail with it in place. Joel reasons they put it there for a purpose. If Spark cannot point high enough under sail, he will drop the lead and rebuild the centerboard the next time he hauls her out of the water.

The most time-consuming part of the restoration was recorking, or recaulking, the seams. “Every single seam you see between the planks if full of cotton.” Cotton is fed into the joints with caulking irons, then filled over with a tar and oil mix pushed into the seam with a two-inch knife blade. “It’s a traditional boat building skill that apprentices, like shipwright apprentices, can do their whole life and still not be a professional.” Joel’s father figured they recorked about two-and-a-half-miles of seams.

A view of the windlass from inside.Surprisingly, Spark needed only two of her planks replaced. Most of her hardware is original to the boat, including the manual anchor windlass. Joel had no choice but to gut the interior.

Before … (Photo provided by Joel Kellogg)… and after.[page]

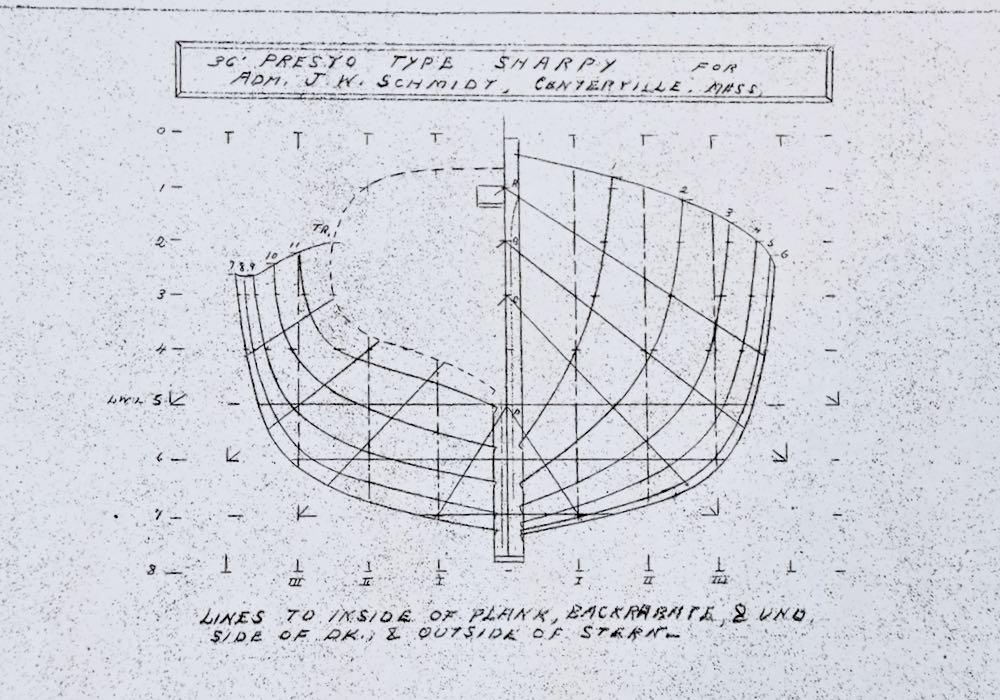

The original manual anchor windlass.Joel found the original plans at Penobscot Maritime Museum and got a paper copy showing the design was drafted in 1972 by R.D. Culler, also known as “Pete” Culler. It was built for Rear Admiral John W. Schmidt, well-known for his paintings of nautical themes and landscapes, specifically for his depiction of the frigate USS Constellation.

There is little information about Spark during the time Schmidt owned her. Joel says the previous owners knew next to nothing on the subject. However, he did find a YouTube video with a few seconds of footage from that time. Though she carried the name Spark from the beginning, the yellow, green, and red color scheme came after her time with the Rear Admiral.

The plans Joel had gotten presented another mystery: her design name. Original plans call her a ’36’ Presto-Type Sharpy.’

Details from the original plans describe Spark as a ‘Presto-Type Sharpy’.“When I heard ‘Sharpie,’ I was like, ‘that’s not a Sharpie,’” Joel says. “A Sharpie is a small, shallow draft, 12-14 foot day sailing boat. Like inland, shoal water sailboat.”

His boat, he says, is “not anything like that. But it does kind of resemble it if it had a centerboard and it was way smaller. It’s just an interesting bit of knowledge I’ve had arguments with people around Oriental about.”

Those discussions have included the staff of TownDock. We asked for input from a few area residents who know a thing or two about boats. Both Tom Lathrop and Graham Byrnes conclude that the terms Sharpie and Presto have been widened to include a variety of designs since their inception. Both point to the Presto as a boat initially designed by Commodore Munroe for the Florida Bays and Keys while the Sharpie was a decidedly more northern vessel. The Mystic Seaport Museum has weighed in by offering copies of Pete Culler’s design, changing ‘Sharpy’ to ‘Sharpie,’ and leaving the rest alone.

Joel assures us these lights will eventually be replaced. Great for restoration work; not for sailing.Restored and freshly painted decks.However Spark is called on the plans, Joel calls it a centerboard, gaff rigged ketch. And he plans to make her a working boat. Joel is a diver, trained by NOAA. He logged hundreds of dive hours working with research ships in the Arctic. He’s sailed all over the world and single-handed a boat in the Pacific, but wants to take Spark out to the Pamlico Sound to the Graveyard of the Atlantic. “That’s one thing I plan to do with this boat, take it out and dive some of the subs and different ships out at the graveyard…I intend fully to get out and do some diving and fishing.”

A temporary bunk was installed for her first night back on the water. It wasn’t necessary; Joel did not sleep that night.Spark went into the water at Sailcraft on September 30th. Joel built a makeshift bunk, lashed a mini fridge to the frame, place a few bilge pumps in the hull, and prepared to spend the night while she rested in the slings. He waited and counted while the pumps cycled on and off and Spark’s boards expanded. He did not sleep that night, waiting to see if the work would hold.

Spark in the slings.Joel and Alan Arnfast survey the water pooling in the bilge.The next morning, the pumps cycled a little less frequently and the slings were slack. Spark, while not yet seaworthy, had passed her first test. She was rafted at Sailcraft while Joel returned to work.

With the masts off Spark’s decks, new rigging is easily installed.There are more projects to be done. When the mizzenmast fell and ripped a hole in the deck, it shredded the sails. Those that weren’t damaged in the fall are in poor repair. An engine currently rests in Asheville, well pickled in oil, waiting to be rebuilt. Some of Joel’s friends and co-workers will return to help him restore the interior.

Spark is not meant to be a museum piece. “It’s not going to last forever. It’s gonna be a certain point where Spark’s had her day, you know? But I want to use it while she’s here. Push her to her limits.”

Joel adds the finishing touches.For now, Joel is taking a break, keeping his weekends for himself. The work has paid off; Spark sits at the docks and her pumps only run occasionally. He is content to wait and see how she handles the water and the weather before moving ahead. Soon enough, he will be back working on Spark, restoring her until she can sail the Sound.

Spark as she is today.