It's Saturday April 20, 2024

Lots of boats come to Oriental, some tie up at the Town Dock for a night or two, others drop anchor in the harbor for a while. If you've spent any time on the water you know that every boat has a story. The Shipping News on TownDock.net brings you the stories of the boats that have visited recently.

August 22, 2014

Jim Coward’s passion is improving the fuel efficiency of trawlers and pleasure cruisers. He says, “there’s no reason power yachts should be heavy, lumbering beasts which constantly demand to be fed.”Jim decided to do better. He would build a super fuel efficient 50 motor cruiser. He had no offshore boating experience. He did have a garage. Using common tools and materials, he built his version of the perfect cruiser. Her name is “Audacity”.

Audacity in her slip at Whitaker Pointe Marina.

Audacity in her slip at Whitaker Pointe Marina. Jim Coward at the helm of his moored craft.

Jim Coward at the helm of his moored craft.The 50-footer is the prototype of a class of vessels Jim calls the Xenocraft. The vessel is 50 feet long and draws 20 inches. From outrigger to outrigger, she is 21 feet wide. She looks more personal jet than trawler. He says, “in the future, gasoline will cost $8 or $10 per gallon, and only the very rich will be able to afford to go boating.”

Jim felt the boat’s long, lean lines would make her efficient. This would allow people of moderate means to own and operate a large cruising vessel. It would also lighten the boat’s environmental impact. Audacity is designed to run on two 6 horsepower outboard motors.

Jim prepares to go below. The console, steering wheel and windshield are off a Bertram power boat. Though not presently hooked up, the controls will lead…..

Jim prepares to go below. The console, steering wheel and windshield are off a Bertram power boat. Though not presently hooked up, the controls will lead….. …to an outboard motor mounted between the main hull and each outrigger. Here, the starboard outboard. The port engine is currently not mounted. Audacity does not have a rudder. Instead, when both her outboards are hooked up, Jim says they will be used to maneuver the boat.

…to an outboard motor mounted between the main hull and each outrigger. Here, the starboard outboard. The port engine is currently not mounted. Audacity does not have a rudder. Instead, when both her outboards are hooked up, Jim says they will be used to maneuver the boat.Jim grew up in Savannah Georgia. As a teenager, he built small boats – rowboats, catamarans, sailboat and trimarans. He was interested in efficient designs, hull shapes that were easily moved through the water with a minimum of energy. He avoided sailboats. “I was interested in mechanical simplicity,” he says. “Going to sails and rigging defeats simplicity.”

He dreamed, one day, of building a large boat that could go a long way on a little bit of fuel. Instead he went to Georgia State.

At State, he got his masters in Public Administration and completed most of his doctorate in Political Science. His dissertation was on the political sophistication of the American electorate. He says his committee denied his dissertation, “because they viewed my beliefs as too radical.

“What I learned from my thesis,” he says, “is that the American electorate isn’t very sophisticated.”

Audacity has some features that might appear unsophisticated. The cross beams that connect the main hull to the outriggers – and support the outboard – are made of aluminum box beams. Three of the 2” by 6” beams are bolted together to make a single outrigger. Jim says the advantage to this system is if the cross beams ever break or suffer metal fatigue, they are easily replaced. Rubber mounts in the hull act as shock absorbers.

Audacity has some features that might appear unsophisticated. The cross beams that connect the main hull to the outriggers – and support the outboard – are made of aluminum box beams. Three of the 2” by 6” beams are bolted together to make a single outrigger. Jim says the advantage to this system is if the cross beams ever break or suffer metal fatigue, they are easily replaced. Rubber mounts in the hull act as shock absorbers.In hindsight, he thinks it worked out for the best. “If I’d gotten my PhD, I’d have taught at a community college somewhere. I wouldn’t have had a chance to build a boat.”

[page]

Jim moved to Oriental in 2007. He bought a waterfront home on Styron drive. He set up a shop in his garage and in 2010 started building what he hoped would be the most fuel efficient power boat in the world.

Though he’d built small craft as a young man, he had never built a vessel this size. He describes his boating experience as traveling “hundreds of miles” in boats, none of them offshore. Still, he knew exactly what he wanted to create.

As Jim saw it, the trouble with most large trawlers and power cruisers is they were all the same – heavy, slow and fuel thirsty.

The solution was to give the world the exact opposite kind of boat – something large, lightweight, fast, and fuel efficient. That meant turning his back to what had already been done. It meant ignoring conventional wisdom.

He says, “I wanted to operate from ignorance. I did not want to be influenced by other designers. I wanted to keep the underwater dimension of my design narrow to define the Planing Principles.” What Jim calls “Planing Principles” is also known as Hull Speed. It is a mathematical limit to how fast a displacement hull – a hull that rides in, not on top of, the water – can travel.

Audacity’s narrow hulls, with which Jim hopes to defy the principles of Hull Speed. Hull Speed is the maximum theoretical speed a non- planing hull can travel through the water. Jim felt his design could do better. So far, Audacity has been towed by a skiff but has not been able to break this law of fluid dynamics.

Audacity’s narrow hulls, with which Jim hopes to defy the principles of Hull Speed. Hull Speed is the maximum theoretical speed a non- planing hull can travel through the water. Jim felt his design could do better. So far, Audacity has been towed by a skiff but has not been able to break this law of fluid dynamics.To avoid copying what he considered defects in other marine designers’ boats, he started from scratch. “I didn’t build the boat from a set of plans,” he says, “I built it by eye. I kept playing with the wood until I got the curves where I wanted them.”

The frames, the wood equivalent of ribs in a person, were built of hardware store plywood. He used long strips over softwood timber to connect the frames. The vessel’s outer skin consists of 1/8” luan plywood – “doorskins” he says.

To keep the resulting structure dry and add rigidity, he sheathed the hull with fiberglass.

Audacity’s aft compartment. The metal beams connect the outriggers to the main hull. This area traditionally houses a vessel’s steering gear. Not so Audacity. She has no rudder. Jim plans to steer the vessel using outboard motors, one mounted on each side of the vessel.

Audacity’s aft compartment. The metal beams connect the outriggers to the main hull. This area traditionally houses a vessel’s steering gear. Not so Audacity. She has no rudder. Jim plans to steer the vessel using outboard motors, one mounted on each side of the vessel. Jim stresses Audacity is a prototype for what he hopes to be a line of commercially built vessels. As such, she is cluttered – a work in progress. Here, below the companionway, the proposed site for a galley.

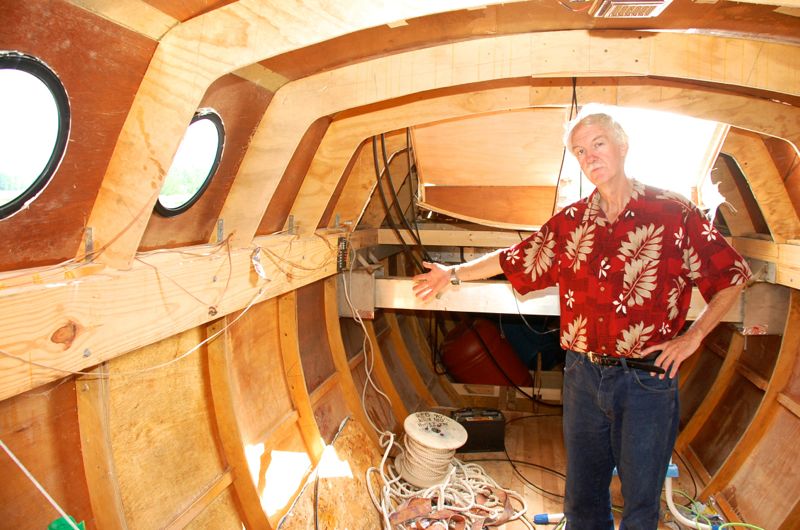

Jim stresses Audacity is a prototype for what he hopes to be a line of commercially built vessels. As such, she is cluttered – a work in progress. Here, below the companionway, the proposed site for a galley. Jim steps in to Audacity’s forward compartment. His hand is on one of the bulkheads that will separate the head compartment from the rest of the cabin.

Jim steps in to Audacity’s forward compartment. His hand is on one of the bulkheads that will separate the head compartment from the rest of the cabin. The bow compartment showing Audacity’s plywood frames and luan sheathing. Jim plans to fit out the space with an anchor locker and a berth.

The bow compartment showing Audacity’s plywood frames and luan sheathing. Jim plans to fit out the space with an anchor locker and a berth.To control costs, Jim used materials not normally associated with marine use. The vessel, after all, was a concept vehicle. “You don’t want to spend all your money on the prototype,” he says, “because that wouldn’t leave anything over for production.” If the concept worked, he hoped to build the vessels commercially. The hull would serve as a mold for future boats.

Much of the wood came from building supply stores. The fiberglass cloth and polyester resin – used to give the wood an external, water proof skin – he bought directly from the manufacturer. “I used three, 55-gallon gallons of resin,” he says of the construction, “which I’d say weigh about 1,500 lb.

Jim found an inexpensive substitute for bronze ports. “I used van portholes,” he says. “They cost forty dollars each.” He sealed them in place with marine caulk.He worked mostly alone. “I had a girlfriend that worked on it for 10 minutes,” he says. “Then she quit. She really wasn’t in to boat building.”

Jim found an inexpensive substitute for bronze ports. “I used van portholes,” he says. “They cost forty dollars each.” He sealed them in place with marine caulk.He worked mostly alone. “I had a girlfriend that worked on it for 10 minutes,” he says. “Then she quit. She really wasn’t in to boat building.”[page]

To build the 50-foot vessel in his much shorter garage, Jim built the main hull in in 3 parts – one long mid-section and two shorter bow and stern pieces. The process looked like this: (Jim Coward photos).

The bow section. The vertical plywood frames support long strips of softwood to which…

The bow section. The vertical plywood frames support long strips of softwood to which… …the skin is attached. The 1/8” thick strips of luan were clamped, glued and screwed to the frame work with screws. When the adhesive dried the screws were removed.

…the skin is attached. The 1/8” thick strips of luan were clamped, glued and screwed to the frame work with screws. When the adhesive dried the screws were removed. The bow section “planked” with strips of plywood.

The bow section “planked” with strips of plywood. To move the long, main central section of hull, Jim drove his Honda inside, lowered the structure on the bumper and drove…

To move the long, main central section of hull, Jim drove his Honda inside, lowered the structure on the bumper and drove… …to the backyard where he joined it up with the bow and stern pieces. For strength, he covered the joints with strips of fiberglass and resin. Then he coated the entire hull with additional layers of heavy fiberglass cloth and more polyester resin.

…to the backyard where he joined it up with the bow and stern pieces. For strength, he covered the joints with strips of fiberglass and resin. Then he coated the entire hull with additional layers of heavy fiberglass cloth and more polyester resin.When the hull was deemed strong enough, with the assistance of friends, he rolled it over.

At this point, the hull was open, like a large dugout canoe. To close it in and add standing headroom he built a cabin house, or as Jim calls it, a “freeboard enhancement”.

Audacity was launched in March 2013.

Jim’s back yard faced Pierce Creek. When the main hull was ready to float, he set up an arrangement of greased skids, cargo straps and a come along to pull the hull in to the water. Come launch day, Audacity’s hull didn’t slip in to the water quite as easily as hoped. For extra power he says, “I gently bumped the transom with my 2002 Acura.”

Audacity, floating behind Jim’s house. With her fresh coat of paint and streamlined hull, she appears more star ship than garage built cruiser.

Audacity, floating behind Jim’s house. With her fresh coat of paint and streamlined hull, she appears more star ship than garage built cruiser.Jim’s boyhood dream of designing and building an efficient power cruiser was up and floating.

[page]

Since launching, Jim hasn’t put much mileage on Audacity. To see how efficiently she moves through the water, he towed her with another vessel. The tow vessel was equipped with a 6 horsepower outboard motor. Jim calculates he was able to tow Audacity over 12 miles on a gallon of gas. He was moving at under 4 knots.

For a while, Audacity was moored behind Jim’s house. Later she was moved to Whitaker Pointe Marina.

Audacity at the Whitaker Pointe Marina dock.

Audacity at the Whitaker Pointe Marina dock.The closest she has come to sea trials is heavy weather at the dock. Jim says, “I baby sat her during Hurricane Arthur. I’m confident she could get through a hurricane anchored in a creek. I observed how she did in the wave action. She did very well. The conditions are like what she might encounter at sea.”

At this point Jim can look back on the project with hindsight. He sees a mix of success and failure. “Operationally it’s a success. I’ve seen it floats. I see how it travels. The boat is vindicated.” he says. He plans to continue making improvements. A second outboard motor and an anchor well are planned.

“Commercially,” though, he says, “it’s a failure. “

Jim had hoped to put his boat in to production. So far, that’s proven difficult. He says the reason is largely economic. “People who can afford a boat of this dimension don’t care about the fuel cost. Even if gas is 8 or 10 dollars, they just go ahead and fill up.”

The boat’s long, narrow layout has also proven a hard sell. He says, “boaters these days expect bigger accommodations. They want a house to drive. They don’t want efficiency.”

Still, one man was very interested in Audacity.

He bought her.

Jim says he sold Audacity to, “a New Zealand national doing business in Egypt. He’s raising money in Egypt to buy two 25-horsepower outboards. When he gets back, he plans to take her to South America, possibly to do eco-tours in the Amazon.”

Jim walks away from Audacity. She may soon leave Oriental – without him.

Jim walks away from Audacity. She may soon leave Oriental – without him.Jim says the new owner, “wants me to co-pilot for him.” Of jumping aboard and heading south he says, “I’m not sure I’ll take the trip.”